It’s been raining in southwest Mississippi, and rain can get in the way of A) digging holes in the ground, B) sticking cardboard tubes into them, and C) pouring concrete. It was the rain that kept us from doing the piers the last time I was in Mississippi.

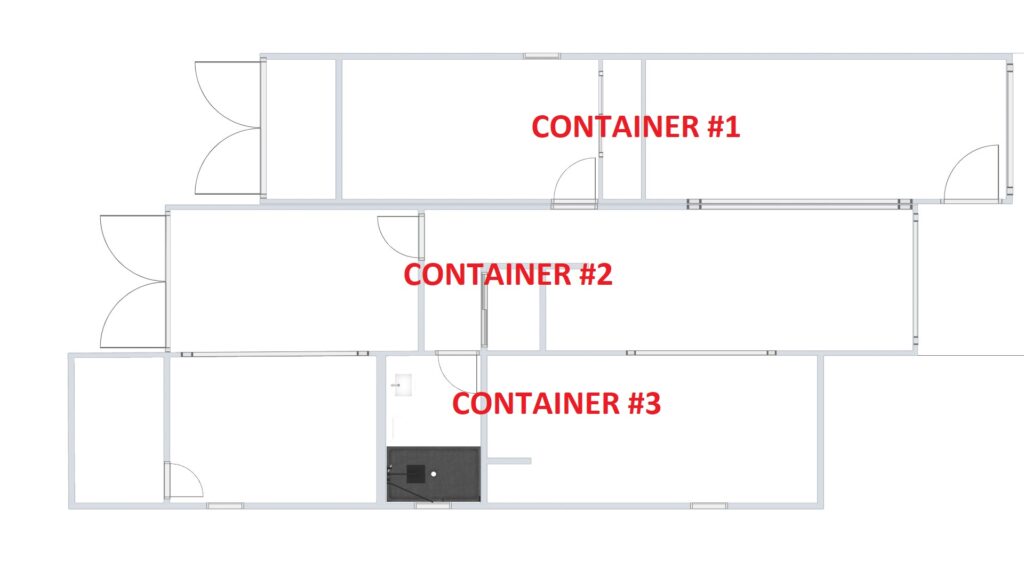

But the forecast was only for spotty showers this trip and I was determined to get these things built. There’s really nothing left to be done in Container #1 until much later: drywall, flooring, HVAC, etc., and I can’t afford to waste my trips to Mississippi.

Even before I could lay out points on the lawn where the new piers would go, we made a design alteration. I’m generally averse to midstream changes, but this one occurred when Calvin suggested it while we sat at the bar at Applebee’s, where the Happy Hour Chardonnay may have loosened my reticence.

Our original design called for two 40-foot containers and one 20-footer, our thinking being the last one needed to be big enough only for the kitchen and bathroom.

But it occurred to Calvin that turning that into a 40-foor unit would provide room both to expand the kitchen and bathroom and to add more bedroom space. This would mean that the primary bedroom would move over to this side of the house, and what was to have been the bedroom, in Container #1, would become a smaller guest room.

The larger containers don’t cost much more than 20-foot ones, and the idea of a larger kitchen appealed to me, so back to the drawing board I went.

It was easier plotting points for this container’s piers than for the first one. For the previous effort we started from scratch, which meant calculating precise 90-degree corners, checking measurements not only along the edges but also on the diagonals.

This time, however, we had only to measure away from the existing container.

Before attaching the cardboard tubes to the Redi-Base forms as before, we estimated the height required for each and cut them a foot longer. It would have been disastrous to get a tube in the ground, only to discover it was too low. (My understanding of) best practice is to have as much of the pier in the ground as extends above ground, but this might not have happened here. There was an element of, “Yeah, that’ll do,” on my part during the digging of holes. Fingers crossed.

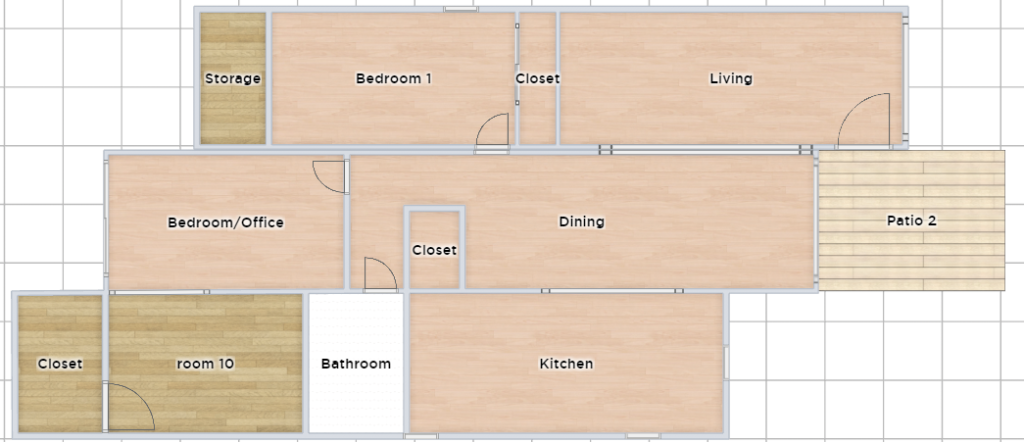

The container is attached to the piers by welding it to steel plates set in the concrete. On the first container I made a silly mistake. I documented it here and won’t wallow now in my shame.

These are the steel sculptures that will go into the wet cement at the tops of the tube forms. The rebar is welded on at cockeyed angles on purpose, to minimize their extracting themselves from the concrete. I can’t imagine how that might occur with a five-ton box resting on one of them, but you can’t be too careful is my motto.

My friend Sammy and his crew have handled the dirty part of hole-digging on the previous dig-sessions but they weren’t available this week because they were busy catching up on jobs they were rained out of last week. So I rounded up a couple of other guys — Shane, who is a friend, and Jamel, who is a cousin of a friend — and rented the auger.

Jamel didn’t have a trailer hitch, or whatever the thing is called that sticks into the square bracket at the back of the truck and has a ball on it. I assumed that the equipment-rental place would have these for hire. I assumed it but I was wrong, so we had to drive down Presley Boulevard to a hardware store, where I forked over 70 bucks for a hitch-thing with a ball on it. I don’t like surprises.

When the folks at Quality Rental Center of McComb hand over your Ground Hog HD99 auger, they run through a how-to list as long as airline pilots must use to get a 787 off the ground.

“You release this part here with this cotter pin, then put the cotter pin down here in this hole — see here? — then click this red switch to the right. Then you flip the handle back this way — watch your fingers — until it locks. Turn the switch at the top on, then turn the gas and choke on. See right here? There’s another switch on this side you have to turn on, too. Come around here — see that? Now, when you’re done, turn off the gas and let it run for about 15 seconds till it stops, THEN turn off the switch up by the handle. Got it? Now it’s really important to have the gas turned off before you tow the thing; if you don’t, there’ll be a 25-dollar charge.”

Here he stressed the point by directing our attention to the top of the auger, on which was written in Sharpie, “Turn gas off before towing!! $25 fee for not doing so!!”

“You got all that? Just bring ‘er back with the gas topped off.”

“I think so,” I said. After the man walked away I turned to Jamel and asked, “Did you get all that?”

“Between the two of us we probably got it,” he said.

You can’t drive very fast when towing a Ground Hog HD99, especially in a place with streets as bad as McComb’s. You hit a bump or pothole and it briefly becomes airborne.

Once at the house we recalled enough of the instructions to fire up the machine, and the excavation commenced.

Things moved along well, especially since, because I’d hired two helpers, neither Calvin nor I had to do much actual digging. I checked hole-placement using my strings and batter boards, and once satisfied with one hole we moved to the next. I also acted as job superintendent.

As is visible in the pictures, our yard slopes down toward the rear, and the containers therefore rise far higher from the ground there than in the front. This meant that the holes for the piers back there needed to be correspondingy deeper. This is where we discovered, in case we hadn’t known, or cared enough to research the matter, where the water table is in our part of Pike County.

About three feet down, water began seeping into the hole, not a flood but definitely a trickle. After it reached about three inches in depth it stopped rising.There would be no point in scooping the water out, and because I didn’t want to set my Redi-Base in, and pour concrete into, the pool down there, I devised an ingenious solution.

First I dumped a couple of bags of crushed rock in the hole to raise the floor a little — about to the surface of the subterranean puddle. I then wrapped the entire Redi-Base in heavy plastic obtained by cutting open a contractor-size garbage bag. I taped the plastic to the sides of the form and set the whole thing in the hole. This would keep the fresh concrete out of the water when we poured it.

The downside of this process was leaving less of the pier buried relative to what’s above ground. In the end, the two piers at the rear of the new container go down only about two-and-a-half feet, with three-and-a-half feet above ground. The situation isn’t ideal but it’s what we have.

I braced the tubes plumb, and backfilled and tamped.

THE WEATHER

Mr. Sammy was available over the weekend to pour concrete but rain was expected for Saturday (today). The plan was therefore to meet him early Sunday at Lowe’s to buy the concrete. Sammy stressed doing this job as early as possible in the day, and it only hit me later that it’s Super Bowl Sunday (tomorrow, as I write).

The rain has been light but constant today and is expected to end this evening. To protect the cardboard tubes and minimize the chance of the ground around them becoming soaked, we covered and wrapped them and the soil around them in plastic.

I had a dream last night in which I looked outside to see that the tubes had become wet, unstable and buckled.

I awoke from my nightmare in sweat-soaked horror and shuffled immediately to the window to survey the situation, discovering with relief through the pre-dawn haze that everything was intact.

We’ll pour concrete tomorrow, hoping to finish before kickoff.